|

ZX7

Series Counter-Variant DC Arc Welding Machine

|

| This welding machine is a kind

high-efficient and energy-saving welding equipment. With

adoption of advanced integrated circuit control and IGBT (VMOS)

middle-frequency counter-variant technology, this welding

machine enjoys such advantages as easily striking arcs, smooth

arc, small spatter, beautiful welding seam and wide applying

range of currency. It also has such properties as small

volume, light weight, high reliability and easy carrying

about. |

|

¡¡

Safety

notice!

Important

show:

Welding process, not switching function switch to prevent damage to

machines.

For cutting, they must first get rid of the rapid plugs connected with

the welding tongs to ensure continuous welding clamp with the mainframe

to protection against.

Use the safety equipment required to install leakage protection

switching.

Authorized the use of national security supervision departments of labor

protection welding supplies.

The operator must have a valid "metal welding (OFC)

operations," the certification of the special operations personnel.

Electric shock-will cause serious injury!

According to application criteria installed grounding device.

Parts of the welding.

Ensure that the insulation is between you and the ground state and the

workpiece.

Ensure your work place is safe.

Smoke-will be harmful to health!

Let's head to remain the smoke outside.

In welding, the use of ventilation and exhaust devices, to avoid breath

smoke.

Arc radiation-damage your eyes, skin burns!

Suitable welding masks and filters, wear protective clothing to protect

your eyes and body.

A suitable masks or screens to protect spectators from harm.

Fire-welding spark may lead to fire, without confirmation welder nearby

combustibles, please pay attention to fire safety.

Noise-excessive noise harmful to people's hearing

Protect your ears, or put to other use hearing protection ear protective

shelter materials.

Warning bystanders, potential noise will hurt their hearing.

Fault-encountered difficulties, seek professional help.

If you meet difficulties in the installation and operation, please check

the relevant contents of this handbook.

¡¡

DC

arc welding machine

The

welding machine is used in the manufacture of advanced inverter

technology. Study on V-MOS FET devices is the use of high-power inverter

control, 50/60HZ switch to the working frequency for high-frequency

(100KHZ above), and hypotension rectifier. by pulse width modulation (PWM)

DC power source output, the main transformer weight, volume has dropped

dramatically. improve efficiency by more than 30%. Igniter system uses

high-frequency oscillation theory. Their characteristics are as follows

: stable, reliable, portable, energy electromagnetic noise.

Arc

we lding machine is a series of features : efficient, energy, light and

has good dynamic characteristics, arc stability, Rong Chi easily

controlled. The high thrust-load voltage of the energy and better

compensation. A wide range of uses, can be used for high-altitude

operations, field operations, and indoor and outdoor decoration, and is

small in size compared to similar products. light weight, easy

installation, easy operation and so on.

First.

The main technical parameters

1-1.

Parameter Table

|

Parameters

|

ZX7-160

|

ZX7-200

|

ZX7-200B

|

ZX7-250

|

|

Supply

voltage (V)

|

Single-phase

220V¡À15

|

Three-phase

AC380V¡À15

|

|

Rated

input current (A)

|

24

|

32

|

32

|

15

|

|

No-load

voltage (V)

|

70

|

56

|

62

|

54

|

|

Output

current adjustment (A)

|

30-160

|

20-200

|

20-200

|

20-250

|

|

Rated

output voltage (V)

|

27

|

28

|

28

|

30

|

|

Thrust

tuning range (A)

|

-

|

-

|

0-100

|

0-100

|

|

Load

sustained rate (%)

|

90

|

40

|

60

|

60

|

|

No-load

loss (W)

|

40

|

40

|

40

|

60

|

|

Efficiency

(%)

|

85

|

85

|

85

|

85

|

|

Power

Factor

|

0.93

|

0.93

|

0.93

|

0.93

|

|

Insulation

Level

|

B

|

B

|

B

|

B

|

|

Protective

casing grades

|

IP21

|

IP21

|

IP21

|

IP21

|

|

Weight

(kg)

|

8

|

8

|

810

|

15

|

|

Dimension

(mm)

|

371¡Á155¡Á295

|

371¡Á155¡Á295

|

425¡Á205¡Á355

|

480¡Á210¡Á310

|

|

Parameters

|

ZX7-315

|

ZX7-400

|

ZX7-400B

|

ZX7-500

|

|

Supply

voltage (V)

|

Three-phase

AC380V¡À15

|

|

Rated

input current (A)

|

20

|

28

|

28

|

38

|

|

No-load

voltage (V)

|

69

|

67

|

67

|

67

|

|

Output

current adjustment (A)

|

20-315

|

20-400

|

20-400

|

20-500

|

|

Rated

output voltage (V)

|

33

|

36

|

36

|

40

|

|

Thrust

tuning range (A)

|

0-100

|

0-100

|

0-100

|

0-100

|

|

Load

sustained rate (%)

|

60

|

40

|

60

|

60

|

|

No-load

loss (W)

|

80-100

|

100

|

100

|

100

|

|

Efficiency

(%)

|

85

|

85

|

85

|

85

|

|

Power

Factor

|

0.93

|

0.93

|

0.93

|

0.93

|

|

Insulation

Level

|

B

|

B

|

B

|

B

|

|

Protective

casing grades

|

IP21

|

IP21

|

IP21

|

IP21

|

|

Weight

(kg)

|

18

|

28

|

35

|

52

|

|

Dimension

(mm)

|

450¡Á300¡Á290

|

565¡Á305¡Á495

|

540¡Á365¡Á370

|

700¡Á335¡Á630

|

Second.

The installation

2-1.

Power Line Link

1)

Each machine is equipped with a power line. Weld should accept the input

voltage to a corresponding voltage lines, not to accept the wrong

voltage.

2)

Power Connection with the counterparty to a power socket or good contact

to prevent oxidation.

3)

Using Multimeter measuring about whether the value of the input voltage

fluctuation range.

2-2.

The output link

1)

Each equipped with two quick plug welding, the former face of rapid

quick plug socket. Turn to be forced to ensure good contact, to work

long hours of work will be destroyed when the current plug and socket.

This should arouse sufficient attention.

2)

Link to put before the panel welding electrode, the cathode workpiece

then, and red quickly to the other end plugs Xianqian link link hands

with attention within 2.60s board, so that the second cable (on line and

earth) good contact with the rapid plugs, Otherwise, they will burn

quickly plugs.

3)

Should pay attention to the wiring polarity, DC welder general there are

two ways : being wiring and plug;

Normal

Law : Welding then being put anode, cathode then workpiece; (Applicable

to acidic electrode)

Opposition

Law : workpiece then plug anode, cathode then put welding.

(Applicable to stainless steel, cellulose and other basic rod)

According

to the workpiece and welding technology requirements selected arc of

instability will occur if a poor choice. Splash of other large and

sticky, such a situation can easily swap plugs rapid change polarity.

4)

If the workpiece and welding away (50-100 meters). Used in the second

line (on line and earth) long, this should be an appropriate choice of

wire Cross-sectional area greater, to reduce cable voltage drop.

2-3.

Inspection

1)

Whether the standard welder made reliable grounding.

2) Whether all nodes good contacts (especially to Xianqian contact with

the workpiece).

3)

Line of output put it shorted.

4)

Whether the output polarity is correct.

5)

If the choice of circuit protection device leakage current£¼30mA.

6) Welding spatter could catch fire, it is necessary to check the

neighborhood or other combustibles.

Third.

The operation

3-1.

Operation (panel attached map)

1) Open the Power Switch, the first display table set current value, the

fan begins to rotate.

2) Users need to regulate "welding current adjustment knob"

and "arc thrust knob." welding properties meet the

requirements.

3) Under normal circumstances, the value of welding electrodes and

welding current counterparts :

¦Õ2.5:

70-100A£»¦Õ3.2£º110-160A£»¦Õ4.0£º170-220A£»¦Õ5.0£º230-280A¦µ

70-100A; ¦Õ 3.2:110-160A; ¦Õ 4.0 : 2.5 : 170-220A; ¦Õ 5.0:230-280A

4)

"Arc thrust Knob" is used for adjusting welding properties.

especially in a small area with the current "welding current

adjustment knob" used in conjunction, can easily adjust the size of

current arc, and from "welding current adjustment knob"

control, a small current welding, Current thrust will be to achieve

greater energy simulation of the effects of rotation DC welder.

5)

If a welder remote control device :

A Former welder used to determine the location of remote switching

options, as measured by lower home use remote control. ON stall on the

remote control device for home use.

B

Remote control socket plugs inserted correctly, Turn. Prevent barred

from access.

C

No remote control device, to choose their own switch in the

"OFF", or else Current regulation on the plane could not use.

D

Some users in the process of moving welder, remote switching collision

inadvertently put the wrong place, failure to adjust welding. he wrongly

believed that the failure was caused machines to draw attention.

3-2.

Allow duty cycle

1) Requires strict theory of duty cycle. (See Table technical

parameters)

2) Load over sustained rate, in the welding process, welding operations

will suddenly stop, This is a welder overload of work, internal thermal

components action, with the result due to cease operation welder.

Need

not cut off power supply, fan cooling machines continue to operate in

order to expedite the process, generally 5-10 minutes (with the ambient

temperature and ventilation conditions change) will be able to resume

operations. (Note : The candle cellulose electrode, due to upgrade

Thrust)

Fourth.

The attention

4-1.

Use of the environment

1)

The use of relatively dry conditions, air humidity ¡Ü 80%;

2)

Ambient temperature range -10¡æ¡ª+40 ¡æ;

3)

Avoid direct sunshine or rain in the open areas;

4)

To avoid the larger dust or corrosive gases in environment.

4-2.

Safety Summary

1)

To ensure good ventilation conditions

The

welder are smaller and compact structure, the output current is large,

Natural ventilation components heat has been unable to meet demand, the

contents of the fan forced cooling machine.

Please

note : users welder front ends of the exhaust and not covered with

blinds plug ,Welder place at a location away from the surrounding

objects shall not be less than 0.3 m, should ensure that conditions are

improving ventilation. It is critical for the normal operation and

welder life.

2)

To avoid overload

Please

occasional users are all in strict accordance with the maximum allowable

rate under current conditions to limit the current. should not be

overloaded, so as not to reduce the life welder, leading to the burning.

3)

Avoidance Overvoltage

can

guarantee that do not exceed the permissible value of welding current,

If supply voltage provides higher value of the components may cause

damage.

4)

There is a grounding screw on the back of each welder, grounding symbols

for signs, Before the election section in the four-square-mm shell and

wires to be reliable connectivity, not static or leakage causing

malfunctions.

Fifth.

Maintain (please cut off the power!)

1)

Dust regularly, use a clean dry compressed air cleared If Congress and

the smoke pollution in the air using welding, done at least once a month

to deal with dust.

2)

To the required pressure compressed air to avoid damage to the welding

small components.

3)

Internal inspection of the electrical connection is confirmed contacts

good (especially connectors), has reinforced the loose end. If oxidation

use sandpaper to remove the oxide film and re-connect.

4)

To avoid welding inside the flooded or wet, drying is used otherwise,

Measuring with a Megger insulation (including the connections and

linkages between and among shell).

Only

confirmed that there is no unusual circumstances can continue welding.

5)

If do not use of welding machine for a long-term, welding machine shall

be placed in the original packaging and stored in dry conditions.

Fixth.

Troubleshooting

The

following operating requirements : operators must have adequate

electrical aspects of a comprehensive security knowledge and expertise,

Operators should be able to prove their skills and knowledge to the

holders of valid qualification documents.

1¡¢Troubleshooting

common ZX7-160

|

Fault

|

Exclusion

|

|

SMPS

light is not bright.

Fans will not be diverted without welding output

|

1¡¢Confirmed

Power Switch on.

2¡¢Confirmed

the importation of electric power cables accepted.

|

|

Power

indicator light lit up, fans will not be diverted without welding

output

|

1¡¢Then

may be wrong in the importation of 380V power supply, causing

overvoltage protection circuit starter, then changed the 220V

power supply. can be reset button.

2¡¢220V

power instability (excellent long line input) or imported in the

lap lane -- online, Starting Over-circuit caused increased the

diameter line into the grid; s line input nodes, This machine 5-10

minutes after the reset button relations can be restored.

3¡¢Switching

Power Switch for a short period of time caused starter protection

circuit. Shutdown 5-10 minutes after the reset button can be

restored to normal.

4¡¢The

power supply switch to the plate loose lead, re-fastening.

5¡¢24V

power relay board did not pull or damage, an 24V power supply and

relay. Relay can be used with other types of relay replacement.

|

|

Fans

turn, welding control potentiometer output current unstable or

not, sometimes large, sometimes small currents

|

1¡¢Potentiometer

1K, quality, and should not change.

2¡¢Connection

have access to all, particularly connectors and other required

inspections.

|

|

Fans

turn, it is extremely light does not shine without welding output

|

1¡¢Various

plug-ray machines have access to it.

2¡¢Or

have access to the output circuit connecting Department

phenomenon.

3¡¢And

Instrumentation Power MOS plate to plate (VH-07 plugin) voltage

DC380V%

(1)

Silicon Bridge traffic, whether by inserting silicon have access

to bridge

(2)

Power board four large electrolytic capacitor (470UF/450%) among

replace individual leakage

4¡¢MOS

board auxiliary power supply such as a green light does not shine,

please contact the company or dealers

5¡¢The

control circuit questions, please contact the company or dealers

|

|

Fans

turn, very bright light, no welding output

|

1¡¢May

be overcurrent protection, please switch off the machine to be

very bright light, and the reset button can be restored to normal.

2¡¢May

be overheating protection wait 5-10 minutes in the machine can

recover.

3¡¢The

inverter circuit fault may be :

Please

unplug the power MOS mark the main transformer plugs (near Fan

VH-07) reset button :

(1)

If the light is still very bright individual boards MOS FET is

damaged, find and can be replaced with the type of market

management.

(2)

If the light is not very bright

A

Plate may be damaged transformer, Measuring be the main

electricity transformer primary transformer primary inductance and

Q values for parallel L=12.2-2.0mH Q>40

B

Is the second transformer rectifier tube individual breakdown, to

find out and replaced with the type of rectifier tube.

4

May be feedback circuit fault.

|

2¡¢ZX7-250,

ZX7-315, ZX7-400, decent and methods to

|

Fault

|

Exclusion

|

|

No

head table shows

Non-rotating

fan

No

welding output

|

1¡¢Air

switch closure confirmed

2¡¢Then

the input power an electric cable.

3¡¢The

thermal resistance (4) damage (or 24V relay contact closure is not

normally have access points).

4¡¢Power

Panel (floor occur without DC537V output voltage) :

(1)

Bridge circuit silicon, silicon bridge suture have access.

(2)

The power of local boards scorched by fire.

(3)

Air power to the switch plate insert lines, power inverter plate

to plate (MOS board) insert the line

5¡¢The

control board auxiliary power supply part of the

fault.(Manufacturers and distributors or links)

|

|

Head

showed normal

Fans

normal rotation

No

welding output

|

1¡¢Various

plug-ray machines have access to it.

2¡¢Or

have access to the output circuit connecting Department.

3¡¢The

inverter circuit fault (extremely bright light)

Please

get rid of a board inverter power supply line (near the former

panel VH-07 Plug) power cord and transformer (near Fan VH-07

plugin) reset button :

If

the fault is very bright light on the inverters, inverter on the

fault in another.

Next,

turn off any defective power inverter gives the power supply line

(the main transformer power cord is not inserted), then the reset

button :

A

Plate may be damaged transformers, electric bridge and main

transformer primary inductance and Q-value measurements were

measured every transformer.

If

inductance or small replacement

B

Which may be individual plates rectifier tube defects, replacement

2)

If the fault is very bright light in MOS boards, boards of

individual inverter FET bad. the same types of field effect

transistor replacement

4¡¢The

feedback circuit fault (extremely bright light), associated with

distributors or manufacturers.

|

|

Manual

arc welding big fly

|

Link

unreasonable output polarity, output of linear reversed polarity.

|

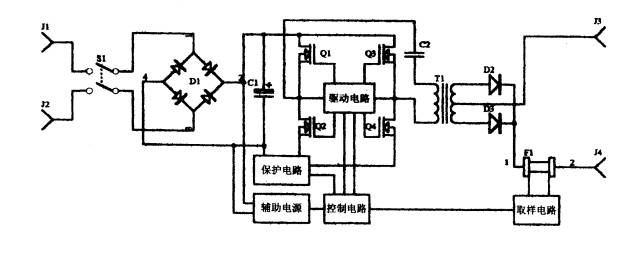

Seventh.

The circuit diagram

Eighth.

Matrix assembly

¡¡

|