|

WSE

Series DC/AC Manual Wolfram Argon Arc Welding Machine

|

| This

series adopts W-CE electrode with argon as protective medium. It is AD and DC universal argon arc welding machines.

It has four functions of use: AC TIG welding, DC TIG welding, AC

manual arc welding and DC manual arc welding. It can weld

high, mid or low carbon steel, non-ferrous metals and its

alloy. It has such properties as wide applying range, easy

operation, stable and reliable performance. |

|

First.

The main purpose and the scope of application

WSE

AC and DC welding machine by using tungsten electrode in argon

atmosphere for the protection of media, use AC or DC arc welding machine

for welding. Welder can be welded carbon steel, stainless steel, alloy

steel, copper, aluminum and other more active resistance to high

temperature and chemical properties of metallic materials. acidic or

alkaline can be used for manual welding electrode. 380V,50Hz welder

using single-phase AC power.

Second.

The main technical parameters and specifications

Specifications

and the main technical parameters shown in Table 1.

Main technical parameters and specifications

in Table

1

|

Project

|

Units

|

Models

and parameters

|

|

WSE-200

|

WSE-315

|

WSE-400

|

WSE-500

|

|

Rated

input voltage

|

V

|

380

|

380

|

380

|

380

|

|

Rated

input current

|

A

|

38

|

65

|

83

|

110.5

|

|

No-load

output voltage

|

V

|

78

|

78

|

80

|

80

|

|

Welding

current scope of regulation

|

A

|

AC:30-200

|

AC:40-320

|

AC:40-400

|

AC:1

stall 33A-200A

2

stall 152A-580A

|

|

DC:20-180

|

DC:30-300

|

DC:38-300

|

DC:1

stall 33A-185A

2

stall 135A-500A

|

|

Admission

arc current scope

|

A

¡¡

|

No

|

30-50

|

30-50

|

30-50

|

|

Admission

arc time

|

S

|

No

|

10

|

10

|

10

|

|

Gas

delay time

|

S

|

10

|

20

|

20

|

20

|

|

Duty

cycle

|

%

|

60

|

60

|

60

|

60

|

|

Torch

cooling

|

|

Without

water

|

water-cooled

|

|

Dimension

(L¡ÁW¡ÁH)

|

mm

|

700¡Á460¡Á750

|

810¡Á490¡Á820

|

900¡Á480¡Á800

|

890¡Á570¡Á900

|

Third.

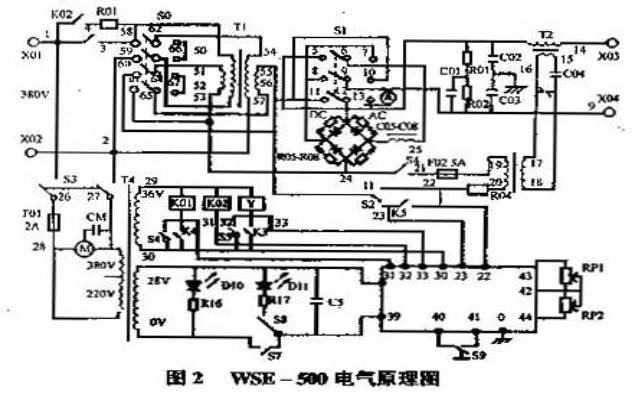

The principle and structure outlined

Welder

used moving core transformer, the full-wave bridge and rectifier filter

inductance is output

characteristics, so that the filter inductor DC welding output, the

current stability in exchange output, the current zero speed.

By

welding transformer, control transformer, single-phase rectifier bridge,

filter inductance, capacitance at DSS. High-frequency oscillator,

transformers, circuit boards and control solenoid valve, the gun and

various switches.

The

aircraft is equipped with a current figure panel installation

instructions, explicit instructions welding current values. Welder shell

shape is beautiful, strong, durable facilitate disassembly, lifting and

transfer characteristics.

The

stability and resumption arc is that the crater fill function that can

significantly improve the quality of welding.

Fourth.

The use and operation

4.1

Welder only allowed to

use at

ambient temperature 5-40¡ãC,

relative humidity of less than 90%. not to allow harmful gases,

flammable and near the desert, steam spray, mold and other occasions.

also prohibited conductivity dust.

4.2Welder

must have good grounding, earthing wire cross-sectional area larger than

the cross-sectional area of importation.

4.3

Welding

power supply from the power grid, power and welding equipment should

control switch. fuse should be consistent with the machine, welding

output line will have to be good insulation and attention to the plane

in line with the supply voltage.

4.4

When the welder used to extend

the distance

from the welding site welding cables, welding cables must be increased

cross-sectional area. welding cable voltage drop is less than four voltage,

burning arc stability can affect the quality of welding.

4.5

Welding operators to be trained professionally familiar with the

technical requirements for the safe operation of aircraft and equipment,

Safety must wear protective equipment, visual arc not prevent

electroslag spatter, so as to avoid adverse consequences.

4.6

Finishing work or leaving the workplace, must be cut off the power.

4.7

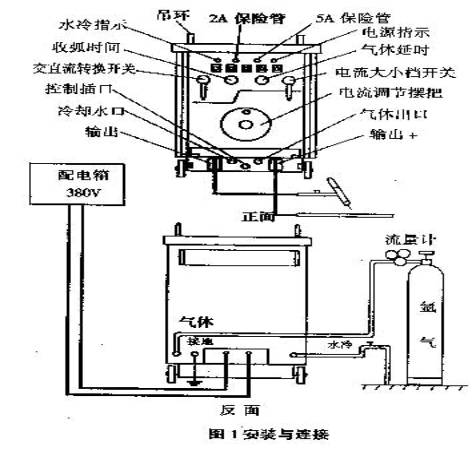

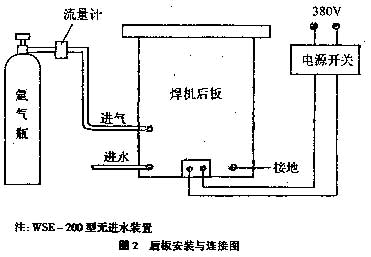

Installed and connected

Installation

and connect Chart

Welding315 : 1. water out 2.gas out 3.

Line of Control Interface

Welding200:

1¡¢2

welder Line of Control Interface 3. Vent Interface

Note

: 1¡¢any

changes to the design, printing faced by welding symbols prevail.

2¡¢when

the welding for manual arc welding, and not Needling gas, water.

4.8

Operating procedures

4.8.1

Using Tungsten Inert Gas (TIG)

A. According to the brochure 4.7,

gas

road and

the lines

are connected all the good.

B.

Face knob and switch to a suitable location, AC-DC switch must grant

place.

C.

According to the current requirements, the use of

regulatory shake

regard to the appropriate location adjustment instructions.

D.

Power Switch appropriated to the "open" position when the

power lights, rotating fans.

Fans

will not be diverted, repair and inspection of stands, not to use.

E.

Frederick Frederick gas income into position switch to gas, argon gas

flow adjustment flowmeter instructions, Switch will be adjusted income

into working position.

F.

Work.

4.8.2

Use SMAW

A.

The

statement by wiring, welding guns will be removed, to take over the

welding tongs.

B.

Switch on the panel will be transferred to the required location.

C.

Regulation shake regard, the spin current direction of the required

position.

D.

Switching power supply will be allocated, the bright light, rotating

fans, a no-load output voltage.

Fans

will not be diverted, not to use.

E.

Started welding.

Fifth.

repair and maintenance

5.1

Welding machine during maintenance or repair, we should cut off the

power supply.

5.2

Welder

regular internal cleansing, casing removed, and air dry cleaning

internal components, parts.

5.3

Factory welder has been transferred to the best electrical sparks up,

the use of such high frequency sparks decline easy arc starting, it

would be appropriate to adjust the electrical sparks up the gap,

reaching arc in the best condition. inspection of the main circuit and

high-frequency oscillation circuit connection and prevent Pretend

welding, Sealing-off phenomenon.

5.4

Welding cable insulation must regularly check whether good, if damage to

be repaired or replaced.

Sixth.

The general troubleshooting

General

troubleshooting table below. Before the repairs, cut off the power the

repair work by competent personnel.

Inspection

failure, electrical diagram reference welder

|

Fault

|

Reasons

|

Approach

|

|

Power

short circuit

|

1.

Switch damage.

2.

Fans short circuit or damage.

3.

Control transformer short-circuit or damage.

4.

Short-circuit or damage to the Line of Control.

5.

Contactors, relays, solenoid valve short circuit.

|

1.

Replacement

2.

Replacement

3.

Replacement

4.

Repair

5.

Replacement

|

|

No

action procedures

|

1.

Control insurance damage.

2.

Damage Control Board.

3.

Control Circuit broken.

4.

Pressure switch damage.

5.

Waterway nowhere.

|

1.

Replacement

2.

Replacement

3.

Overhaul

4.

Replacement

5.

Overhaul

|

|

HF

no sparks

|

1.

Damage HF insurance.

2.

High-frequency circuit nowhere.

3.

Too much dust.

4.

Control Board Damage.

5.

High-frequency transformer damage.

6.

High-frequency capacitance damage.

|

1.

Replacement

2.

Replacement

3.

Clean

4.

Replacement

5.

Replacement

6.

Replacement

|

|

Normally

aspirated

|

1.

Valve damage.

2.

Control Circuit nowhere.

3.

Damage Control Board.

|

1.

Replacement

2.

Overhaul

3.

Replacement

|

¡¡

¡¡

¡¡

|