¡¡

|

¡¡ HEBEI WELDING EQUIPMENTS CO., LTD

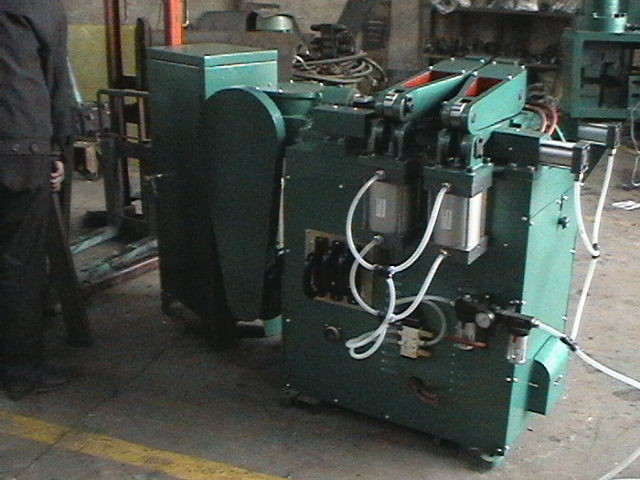

UNT Series High Strength Circle Chain Flash Butt Welding Machine ¡¡ |

¡¡

Unt-160 is controlled by computer program,welding specification can be set in advance, it is a kind of semi-auto circle chain butt welding machine. It also enjoys all the properties of general butt welding machine. Matching units include splinter-removing machine, drawing machine, length-measuring machine, annealing equipment and pneumatic pump station, etc. UNT-250 model high strength circle chain flash butt welding machine is specialized semi-auto butt welding equipment for welding of mine conveyer chain, cement lifting chain, loading chain and non-standard decoration circle chain. It is widely used in coal mine, building material, shipping, petroleum and lifting. This model of welding machine adopts flash butt welding, has characteristics of reasonable design, simple structure, easy operation. It also enjoys all the properties of general butt welding machine. It can weld bars, tubes and other shape materials with changes of fasteners. We may also provide matching devices accordingly.

Structure: This model of welding machine is semi-auto butt welding machine controlled by computer program. It can automatically finish the whole welding process according to the welding program fixed in advance. The welding machine consists body, fastening device, melting and transmission structure, welding transformer, air compressing system, water cooling system and electric-controlled cabinet. Technical Data: |

¡¡

| Model | Specified Capacity (KVA) | Power Voltage(V) |

Continuous Loading Rate(£¥) |

Welding Chain Diameter(mm) |

Secondary Voltage(V) |

Air Compressing Pressure(M/P) | Welding Weight(kg) | Power Frequency(HZ) | Specified Welding Production Rate(Chains/Hour) |

| UNT-100 | 100 | 380 | 20 | ¦Õ8-¦Õ16 | 4.5-7.6 | 0.55 | 980 | 50 | 250 |

| UNT-160 | 160 | 380 | 20 | ¦Õ14-¦Õ22 | 4.05-8.1 | 0.55 | 2700 | 50 | 200 |

| UNT-250 | 250 | 380 | 20 | ¦Õ14-¦Õ28 | 4-11 | 0.55 | 3120 | 50 | 180 |

¡¡

¡¡

¡¡

¡¡

¡¡