¡¡

|

¡¡ HEBEI WELDING EQUIPMENTS CO., LTD |

|

¡¡ |

First.

attention to safety issues 1.1

Installation, use of the former welder, please read carefully the use of

brochures, and to comply with the warning welder website content and language

warning. 2.2

Please professionally trained and professionally qualified staff to be able to

carry out the welding installation, operation and maintenance. 3.3

The use of cardiac pacemakers, without health care professionals, not close to

being engaged in welding operations and the use of welding. energized the

magnetic field generated by the welding work will have an adverse effect on

pacemakers. 4.4

The non- concerned personnel are not allowed to enter welding worksite. 5.5

Not allowed to work outside the welding machine for welding. In

order to avoid an electric shock hazard, please observe the following : Once

exposed live parts may be caused fatal burns and electric shock

1.1

Please do not touch any part of electricity 2.2

Started welding work, should carefully check the importation of power lines to

protect the earth wire and cable insulation and good welding. wiring is correct,

reliable and whether the distribution box and power line capacity to meet the

needs. 3.3 Weld and other protective devices in the demolition of shell off the case should not be used for welding operation¡£ 4.4

The operator must wear protective safety welding supplies. 5.5

Finished welding or welding operations temporarily left the scene, we should cut

off the importation of all welding power source. 6.6

The welder should be regular maintenance professionals. 7.7

Stands as a breakdown of the use of timely inspection, troubleshooting before

you continue to be used. To

avoid arc welding, flying, welding slag, smoke and harmful gas hazards, the use

of protective equipment Arc

light will cause eye irritation and skin burns. Spatter,

welding slag burns to the eyes, skin burns. The

gentle smoke and dust in air is harmful to your health. Narrow

places welding operations, Oxygen deficit is able to lead to suffocation. 1.1

During welding operations or observation, monitoring welding operations, the use

of qualified welding wear protective masks or protective glasses. 2.2

Welding set up around the separation barrier in place to prevent harm to others

arc. 3.3

Wear a mask, welding attention to the ventilation exhaust place to prevent the

occurrence of gas poisoning and suffocation. Especially

in the welding or coated with the coating material, we will create harmful dust

and gases, we must pay more attention to defense. 4.4

Welding in a confined place, the district should arrange for inspections of

ventilation and staff Officers regularly check whether normal operations. To

prevent fire, explosion, bursting the accident occurred, the following

provisions : Spatter

from the welding, welding slag, thermal contact with the workpiece will fuel

fire. power

supply circuit, the welding circuit connecting Department should ensure good

contact, otherwise the work will cause local overheating. In

the absence of effective preventive measures before the ban in sealed containers

filled with a flammable substance or welding. otherwise it would cause an

explosion or burst. 1.1 Welding worksite is not allowed with flammable, explosive or combustible

materials. 2.2

Connection of the cables will be required reliable and good insulation. 3.3

When the welding or sealed container containing flammable material (such as

pipes, boxes, beds, etc.). have to ask the expert to develop effective

preventive measures can do welding. 4.4

In the welding field should be equipped with the necessary safety equipment,

just in case. Contact

rotating parts will cause injuries, the following provisions :

1.1 Please do not demolish the shell off, or other protective devices for the

use of welding. 2.2

Not to fingers, clothes, hair and other parts of the rotation near the welder

(such as cooling fan), to prevent injuries. To

prevent the welding machine and caused fire damage to the insulation properties,

please observe the following rules : 1.1 Welder

placed at the site to ensure welding spatter from the metal powder or other

operations. metal shaving tablets into internal welder, who have found access,

and ensure all of 7659, following the demolition of shell, blowing with

compressed air or other methods to remove the net. 2.2 After

the insulation properties of lead dust accumulation and may even cause an

internal short circuit and affect the normal use of welding, Please light of the

actual situation and send regular maintenance professionals. Second¡¢welding

machines and the main technical parameters of structural features main

use : Weld

way: AC single manual welding arc welding Major

welding materials : steel, low alloy steel structural

characteristic: 1.1 Moving

core arc welding transformer, welding current level without regulation, stable

and easy to use. 2.2 IP21

rating for a protective shell, safe and reliable. 3.3 With

the rings, and the wheel to facilitate the use of lifting and moving a short

distance. 4.4 Small

welder(¡Ü200A) a voltage switch, we can use 220 or 380 Overhead voltage. 5.5 Current

and former board equipped with hand wheel adjustment instructions brands, adjust

current convenience. Main

technical parameters : Welder the main technical parameters are listed below

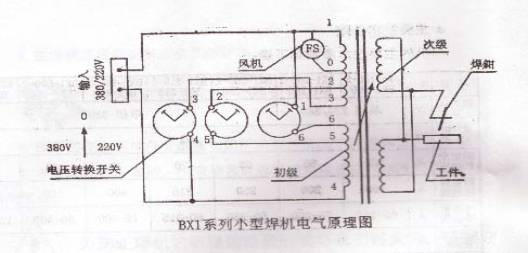

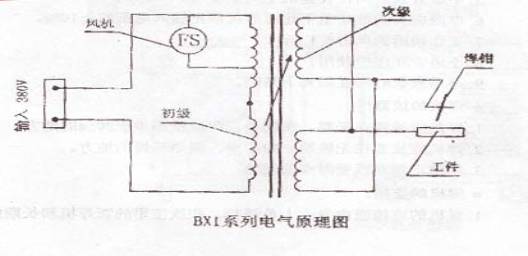

Basal principle£º First. Welding machine electricity principle picture as follows Second. The

basic use The

use of environmental conditions :

1.1 The surrounding

air temperature : -10¡æ

+40¡æ 2.2 Air

relative humidity : at

+40¡æ in: ¡Ü50% at

+20¡æ in: ¡Ü90% 3.3 Ambient

air dust¡¢acid¡¢corrosive gases or substances not exceed normal levels, except

for the welding process. 4.4 Not

more than 1000m above sea level. 5.5 Not

suitable for prolonged use in the salt air. 6.6 Welding

supply voltage fluctuations do not exceed the rated input voltage of ¡À 10%. 7.7 Wind

¡Ü1.5m/s the work place. 8.8 Not

suitable for use in the rain. 9.9 Not

suitable for use in the sun for a long time. welder place : 1.1 Welder should be placed in Steady, less vibration from the walls of not

less than 20cm. 2.2 Welder

should be placed in non-iron, less dust, clean dry place. 3.3 Prevent

rain or water erosion. welder

link : 1.1 Welder link should be professionals. The

initial and long-term use of the new place and then re-use the welder welding,

wiring, Application Megger measuring between primary coil and coil, primary coil

and coil insulation resistance between the frame with no low-1M¦¸. 2.2 Welder

and overcurrent protection switches should be equipped with the exclusive

distribution function boxes (board) , with the capacity to be used for welding

match. 3.3 Connection

between the start, has cut off power supply should be recognized. 4.4 Welder

from the distribution box to recommend the use of the order on the beyond-visual

input power cord soft PVC multiple Copper Wire; Another welder output from the

workpiece (grounding clip) and the link between welding tongs should be used YH

or YHF welding or special rubber insulated cables. 5.5 Welder

earthing recommend the use of cross-sectional area of not less than 6mm2

Core; Using Aluminum Core line, recommend the general area of not less than 10mm2. 6.6 We

have to connect the wiring is correct, reliable. Power lines¡¢cable insulation

should be good. 7.7 Welding

supply voltage is same with the input voltage. The

use of welding Welder

installed after the link, according to the following sequence of operations

(operations should have received professional training. Welding made for

qualified personnel). 1.1 Check all links are correct, reliable. 2.2 Inspect

power lines, welding cable insulation is good, if damaged, Insulating intact or

be replaced with baling wire insulation good. 3.3 Welding

parts that require inspection, it has serious corrosion, paint or other

substantial impact on the quality of welding fixtures, if any, removals should

be clean, so as not to affect the quality of welding. 4.4 Open

distribution boxes (board) on the power switch. 5.5 Opened

the welder Power Switch (for the use of two voltage of 380 volts and 220 volts

small welding machine, it should be noted that : with the power supply voltage

at the switch), rotating fans. 6.6 Current

regulatory hand wheel rotation (stalk), welding, Current former board

transferred to the corresponding instructions needle position (where the value

of the current instructions for reference). 7.7 The

same with the work piece material on the test welding, welding under test

conditions, the optimum welding current to the best value. 8.8 Implementation

of welding operations. 9.9 Welding

operations disposed of (or temporarily left the scene welding). 10.10 Cut

off the Welder power supply. 11.11 Cut

distribution boards (boards) power. The

use of attention : 1.1 Actual

needs of the welding current size, will be workpiece thickness, electrode size

and the influence of factors such as welding positions.

Electrode

with a diameter of the welding current relations have shown in the following

table :

2.2 To

ensure the normal life welder, according to the duty cycle welder and welder to

avoid overload.Weld will set off a serious burn. Welder

rated duty cycle is a very important technical parameters, Weld said it rated in

the actual welding current work in a welding cycle time (10 minutes) the

percentage. For

example : Welder rated duty cycle of 60%, which is rated in Taiwan welder

welding current, Welding allowed under six minutes, four minutes and then empty

the recycling. When

the actual welding welding current is less than the rated current welder,

welding time can be extended.Then load rate calculated by the following formula

: Allowable

load sustained rate = (Rated welding current ¡Â actual welding ) 2 ¡Á

rated duty cycle 3.3 Be

connected to the welding joint firm, otherwise they will be barred from access

to localized overheating and burning or welding cable connector. 4.4 Welding

cables should not be longer than generally should not exceed 15m. 5.5 Welder

prevent rain; To place in cool, dry ventilation, avoid moisture, with iron dust

and placed in many places; In summer, not in

use for long periods under direct sunshine. 6.6 Operators

should wear protective safety complete welding supplies. 7.7 Or

temporary work after leaving the scene, we must cut off the power supply box

welder and distribution. 8.8 Weld

should pay attention to the use of state, found abnormal, should immediately

check stands, remove anomalies can continue its work. Fourth. The

maintenance welder 1.1 Welder maintenance should be professionals, maintenance before 7659. 2.2 Welder

maintenance should be conducted at least once every six months. 3.3 At

least the following maintenance work should be carried out. A

Measuring with a Megger between the primary coil and coil. with the primary coil

and coil insulation resistance between the frame must not be less than 1 M¦¸; B

In addition to using compressed air or brush the dust deposition on the machine; C

Check whether the connecting link firmly and eliminate all connecting

unreliable; D

Check whether firmly fixed coils and other components, must be loosened if

solid. Fifth. General

Troubleshooting Welder general breakdown of the causes and treatment methods are listed below :

Six. Randomly

documents Each

welder at the factory equipped with the following technical documents : 1.1

Use brochures

1 2.2

Certification 1 3.3 Warranty cards. 1 ¡¡ | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

¡¡